Neodymium magnets have become a critical component in the design and operation of various types of electric motors

Neodymium magnets, known for their exceptional magnetic strength and relatively compact size, have become a critical component in the design and operation of various types of electric motors. Here's an overview of their application and usage in this context.

1. **Permanent Magnet Motors**:

- **Permanent Magnet Synchronous Motors (PMSMs)**: Neodymium magnets are extensively used in PMSMs, which are prevalent in both industrial applications and consumer products. These motors are favored for their efficiency and high power-to-weight ratio. The magnets provide the constant magnetic field necessary for the motor's operation, interacting with the electric current in the windings to produce motion.

- **Brushless DC Motors**: In brushless DC motors, which are commonly used in applications requiring high reliability and efficiency (like in drones, electric vehicles, and computer hard drives), neodymium magnets are integral to their function. These motors use electronic commutation instead of brushes, reducing wear and maintenance needs.

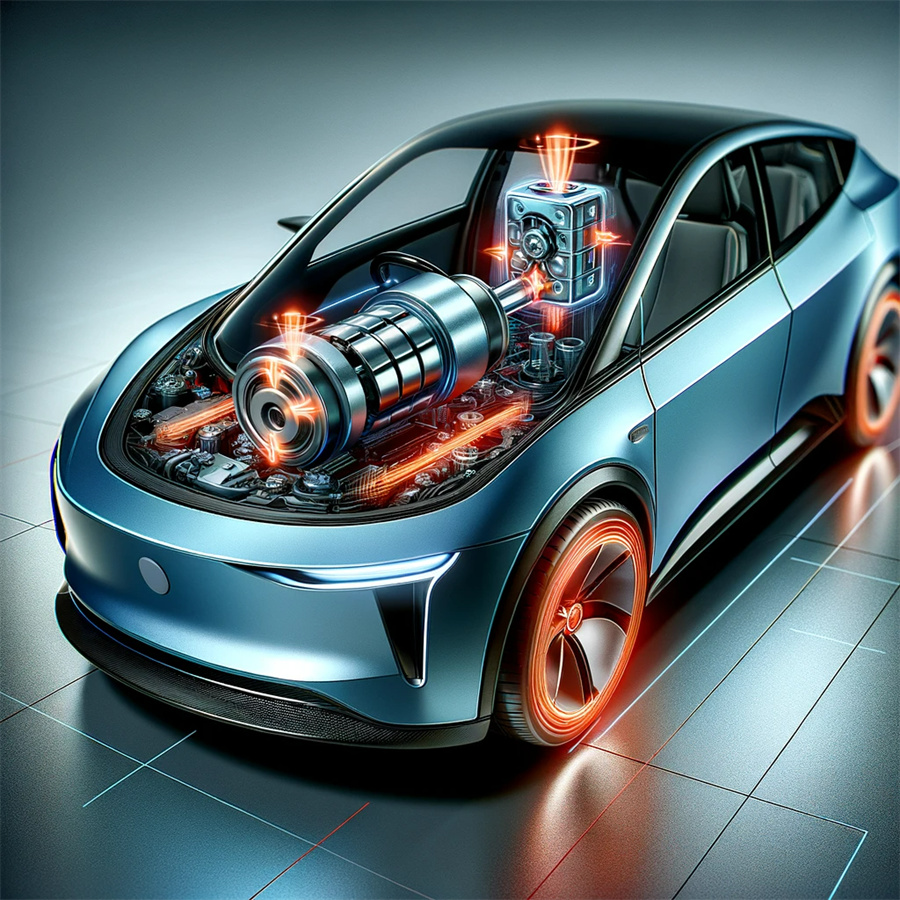

2. **Electric Vehicles (EVs)**:

- Neodymium magnets play a pivotal role in the traction motors of EVs. The high magnetic strength of these magnets allows for the creation of powerful yet lightweight motors, which is crucial for the overall efficiency and performance of electric vehicles.

3. **Consumer Electronics and Appliances**:

- In household appliances like washing machines, air conditioners, and refrigerators, as well as in personal gadgets such as cordless power tools, neodymium magnets are employed to enhance the efficiency and durability of the motors.

4. **Industrial and Robotic Applications**:

- For robotics and automated systems, which require precise and efficient motor control, neodymium magnets are often the preferred choice. Their strong magnetic field enables fine control over motor movements and speed.

5. **Advantages in Electric Motor Application**:

- **High Efficiency**: Motors with neodymium magnets typically have higher efficiency, meaning they convert a greater percentage of electrical energy into mechanical energy.

- **Compact Size**: These magnets allow for the construction of smaller and lighter motors without sacrificing performance, which is particularly beneficial in portable and space-constrained applications.

- **Temperature Resistance**: Neodymium magnets can maintain their magnetic properties over a wide range of temperatures, though they may require special coatings or stabilization for extreme conditions.

In summary, neodymium magnets are a key component in modern electric motor design, contributing to significant advancements in terms of efficiency, power, and miniaturization. Their usage spans from electric vehicles to consumer electronics and industrial applications, although they come with challenges related to cost, environmental impact, and temperature sensitivity.