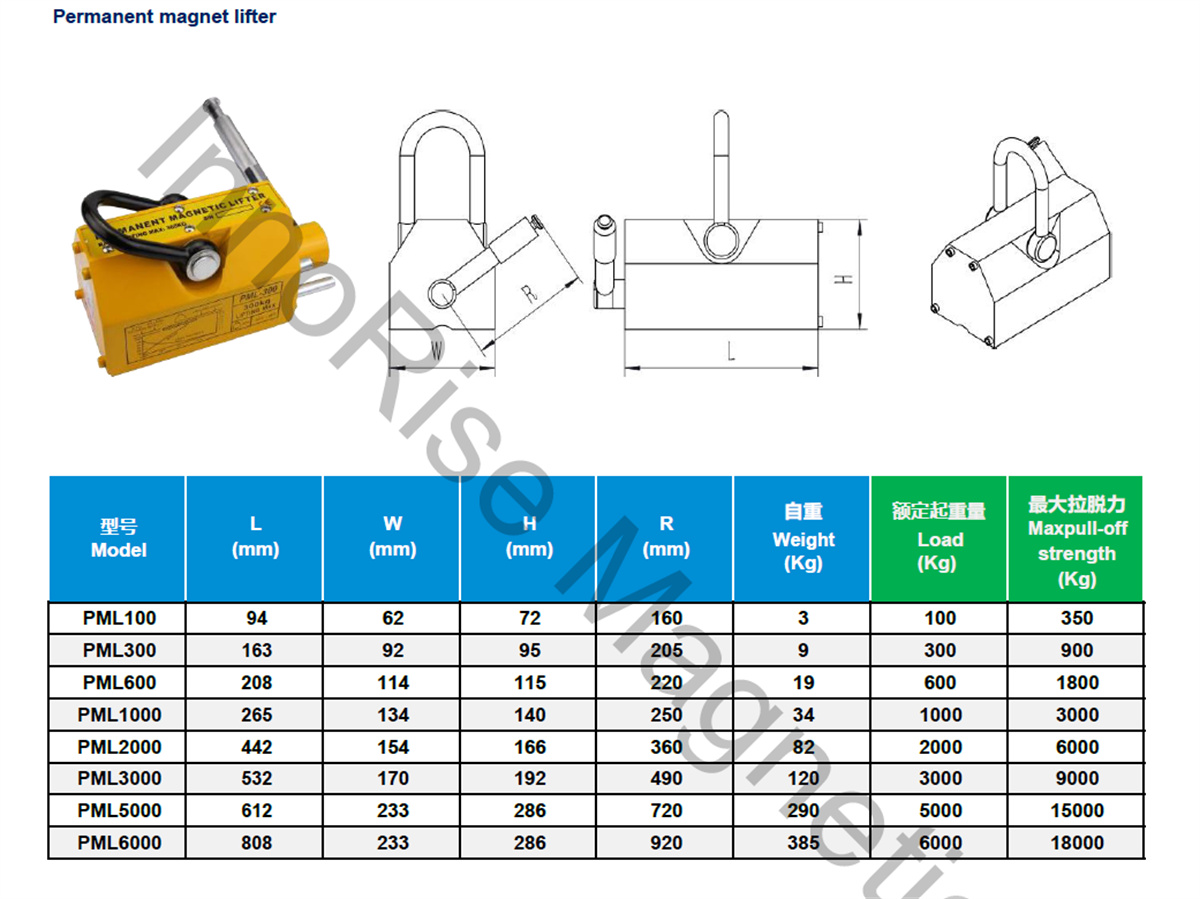

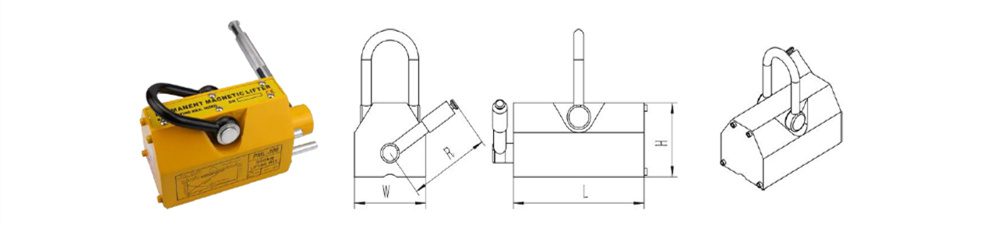

NdFeB Magnet Lifter - 1000KG Lifting Capacity with Strong Neodymium Magnets

Key Features

- Exceptional Lifting Power: Our magnet lifter has a formidable 1000KG lifting capacity, thanks to the high-grade NdFeB magnets, known for their superior strength and durability.

- Secure Handling: Designed for precision and control, the lifter ensures a secure grip on steel plates, boards, and various ferrous materials without the need for slings or chains.

- Versatile Applications: A valuable asset for shop cranes and hoists, this tool is versatile for use in warehouses, docks, transportation sectors, and manufacturing facilities.

- Ease of Operation: With a simple lever mechanism, operators can engage and release the magnetic field, allowing for quick and effortless lifting operations.

- Safety Ensured: The magnetic path is constructed with an advanced design to prevent accidental detachment, providing an additional layer of safety during lifts.

Precautions for use

1. Reasonable use of load: When using the lifter, you need to make sure that the load is in line with the bearing range of the equipment, to avoid overloading caused by equipment damage or personal safety risks.

2. Pay attention to magnet protection: NdFeB magnet lifter needs to avoid collision or impact when using, so as not to cause damage to the magnet surface or magnetic performance decline. At the same time, it is also necessary to prevent the objects adsorbed by the magnet from being damaged.

3. Prevent the magnet from losing its magnetic properties: NdFeB magnets tend to lose their magnetic properties in high temperature environments, so you need to avoid high-temperature places, such as welding areas or near sources of ignition, during use.

4. Regular Inspection: During use, you need to check the magnet surface regularly for any signs of damage, cracks, or loss of magnetic properties, and if you find any problems, you need to replace or repair them in time.

5. Careful operation: When using the lifter, it needs to be operated carefully to avoid impact or friction on the objects adsorbed by the magnet, so as not to cause accidental damage or injury.

6. Storage precautions: For the magnet lifter not in use, it needs to be properly stored in a dry and ventilated place, away from high temperature, humidity and corrosive gases, in order to prolong its service life and keep the magnetic performance stable.

Applications

- Industrial Material Handling: Move large steel plates and items in factories and warehouses.

- Construction Sites: Lift and position steel beams and components with precision.

- Dockyards and Shipping: Load and unload heavy ferrous cargo efficiently.

- Metalworking Shops: Handle bulky metal parts and assemblies safely.

- Automotive Industry: Transport heavy metal components like chassis or engine parts.

Our NdFeB Magnet Lifter transforms the way heavy ferrous materials are moved, enhancing productivity while prioritizing operator safety. Embrace the power of Neodymium and lift with confidence, knowing that your operations are backed by one of the strongest magnets in existence.