0102030405

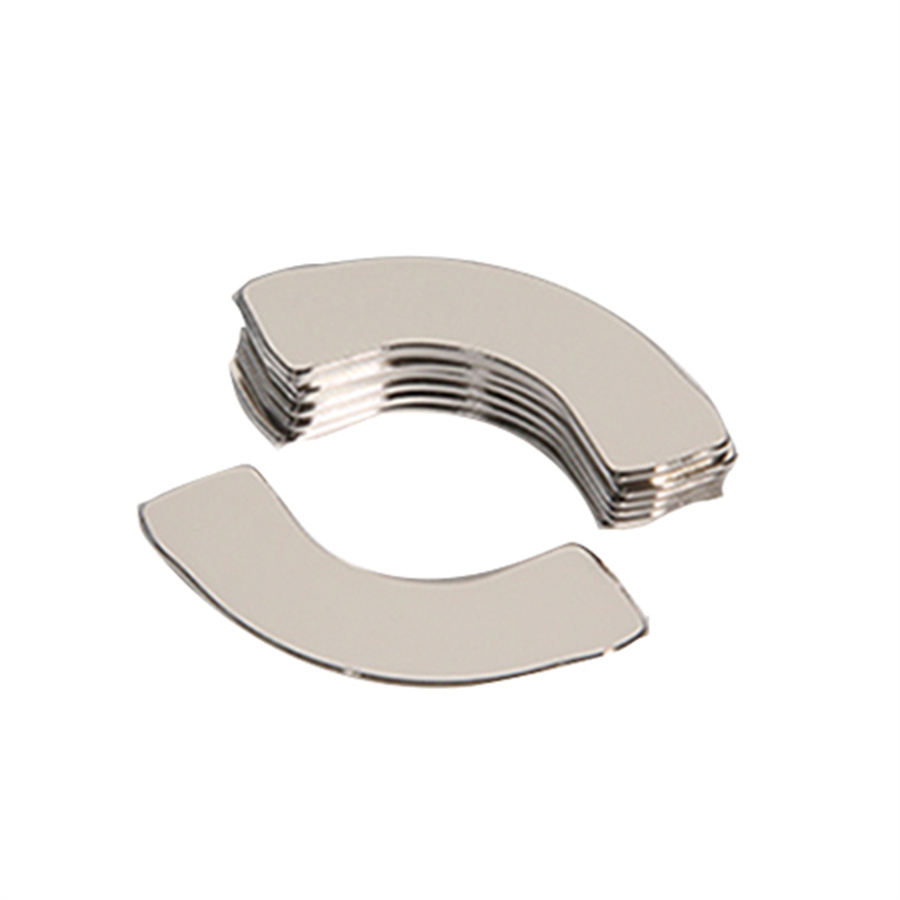

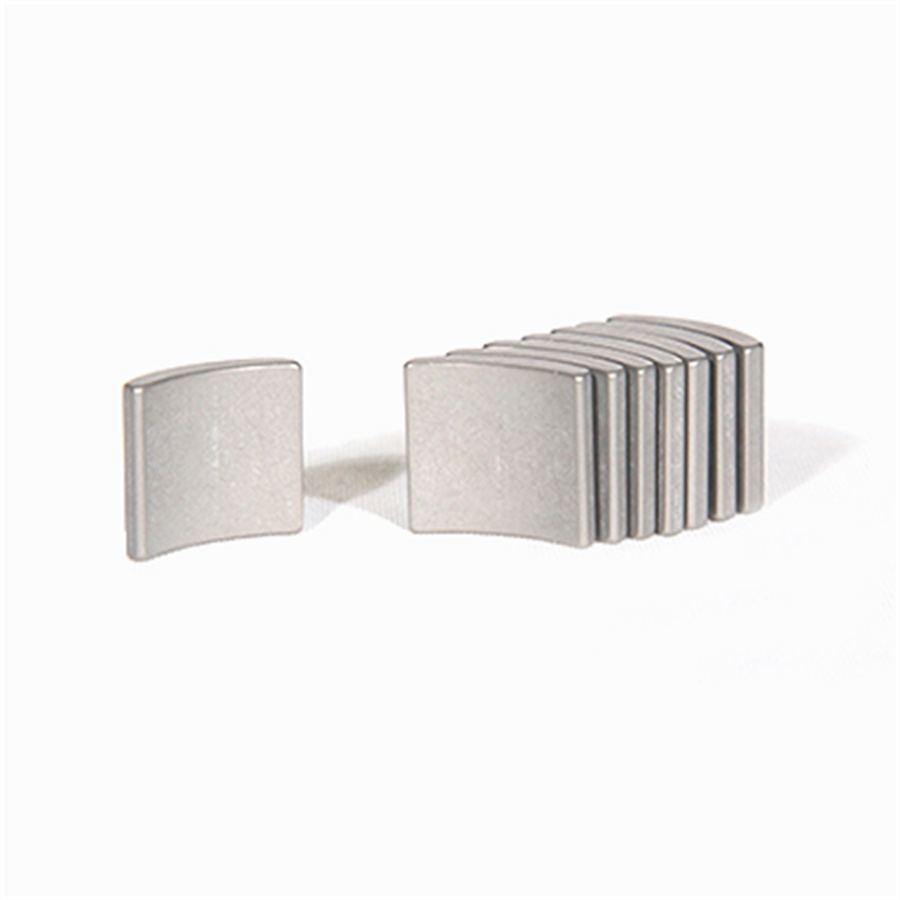

Permanent Ring Strong Neodymium Magsafe Magnet

Product Features

- Great Magnetic Qualities: The motor's great efficiency and power production are a result of its exceptionally strong magnetic qualities, which can create a stable and long-lasting magnetic field.

- Stability: Sintered NdFeB block magnets exhibit strong magnetic stability, resistance to demagnetization, and extended service life.

- Customizable: their size, shape, and surface treatment can be altered to meet the requirements of various motor designs.

Product Applications

- Electric car Motors: Used in electric car drive motors to create a high magnetic field and power, hence increasing motor efficiency.

- Hybrid Vehicle Motors: Used in hybrid vehicle motor systems to improve fuel efficiency and power output.

- Other Electric Equipment: This applies to any electric equipment that requires permanent magnet materials, such as wind turbines and power tools.

Precautions For Use

- Prevent Shock: To prevent damaging the magnet's structure and magnetic qualities, steer clear of intense shocks.

- Temperature Control: To preserve its magnetic performance and longevity, try not to use it in a temperature range that is higher than its rated working temperature.

- Safe Operation: In order to prevent unintentional injuries, one must abide by all applicable safety requirements when operating.

Production Process

- Material Preparation: Choose premium raw materials for Neodymium Iron Boron (NdFeB) magnets, making sure that their physical characteristics and chemical makeup match specifications.

- Verify the magnetization direction in accordance with the application scenarios and design specifications to make sure the magnets have the necessary magnetic characteristics.

- Combining NdFeB powder with other alloy powders in a formulation ratio to get the desired mechanical and magnetic characteristics is known as formulation blending.

- Press molding: Fill the molding die with the combined magnet powder, then press the powder into the magnet blank's specified shape by going through the press molding and pressing blank procedures.

- Sintering process: To increase the magnetic properties, the pressed and molded magnet blank is put through a high-temperature sintering process that combines the powder particles into a solid whole and forms its own grain structure.

- Conduct a magnetic property test on sintered magnets to verify that the design specifications are being met. This test should include measurements of the magnetization curve, coercivity, remanent magnetism, and other indices.

- Final product inspection: To make sure the product quality complies with the necessary standards, the final magnets are subjected to appearance inspection, size inspection, magnetic property test, etc.

- Packaging and storage: To prevent moisture and magnet oxidation, package the eligible products, mark them, and keep them in a dry, non-corrosive gas environment.